Latest News

Flexible Dies & Rotary Die Cutters: Applications and Advantages

Flexible Dies & Rotary Die Cutters: Applications and Advantages

By applying precise materials and cutting technology efficiently, we can enhance the quality of our products. This article will detail the characteristics and application areas of flexible dies and rotary die cutters, explaining why we use flexible dies.What are Flexible Dies? Their Characteristics and Applications

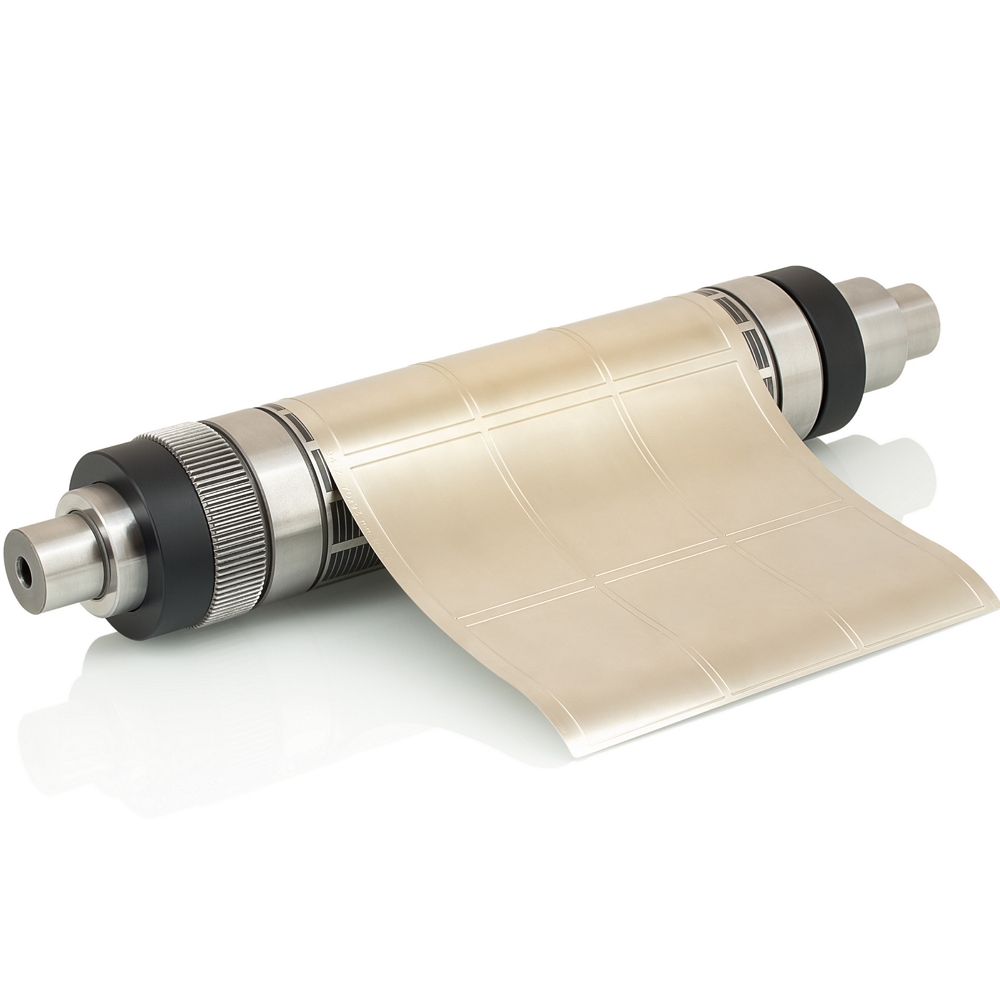

Flexible dies are sheet-like die cutters made from thin steel plates through etching and CNC engraving, offering excellent precision. They operate by utilizing the magnetic properties of the steel plate, which tightly adheres to a magnetic roller. When the machine starts, the flexible dies rotate rapidly, and the material is quickly cut through as it passes the roller.

The Production Process of Flexible Dies

Step 1: Cut and trim the plate to the appropriate size.

Step 2: Apply photosensitive ink on the surface of the plate.

Step 3: Dry the photosensitive ink. Bake the plate in an oven for 10 minutes.

Step 4: Expose the graphics for approximately 30 seconds in a UV exposure machine.

Step 5: Develop for the cleaner surface

Step 6: Use an etching machine to remove unwanted parts.

Step 7: Use CNC to carve the blade.

Step 8: Harden the cutting die (if needed).

Characteristics of Flexible Dies

-

Precision.

-

Smaller-radius angle compared to wooden dies.

-

High production efficiency.

-

Seamless cutting lines.

What are Rotary Die Cutters? How to Use Them with Flexible Dies?

Rotary Die Cutters

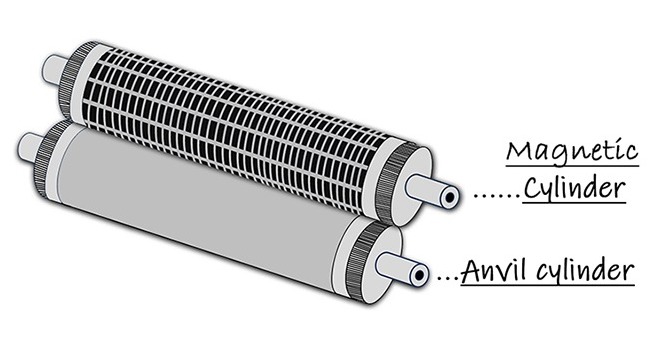

Rotary die cutters, also known as rotary die machines, roughly consist of three main components:

Rotary dies

Anvil cylinders

-

Flexible rotary dies made from thin metal sheets with cutting lines engraved by etching process and CNC and then attached to magnetic cylinders for cutting materials. Flexible dies are very affordable, have quick production times, and are more economical and easier to replace compared to solid rotary dies.

Flexible rotary dies made from thin metal sheets with cutting lines engraved by etching process and CNC and then attached to magnetic cylinders for cutting materials. Flexible dies are very affordable, have quick production times, and are more economical and easier to replace compared to solid rotary dies. -

Solid rotary dies are made from a single block of hardened steel or other durable materials through CNC engraving. They have a long lifespan and can be re-sharpened when the edges are damaged or dull. Solid rotary dies are highly durable and suitable for high-volume production. However, they are costly to produce and have longer lead times compared to flexible dies.

Solid rotary dies are made from a single block of hardened steel or other durable materials through CNC engraving. They have a long lifespan and can be re-sharpened when the edges are damaged or dull. Solid rotary dies are highly durable and suitable for high-volume production. However, they are costly to produce and have longer lead times compared to flexible dies.

(Image courtesy of WOHING LASER MOULD.)

Feeding, rewinder, and waste rewinder

Working Principle

The material passes between the rotary die and roller in a roll-to-roll manner. When the machine is activated, the cutting material moves at the same speed as the roller. As the material passes through the rotary die, it is cut into fully or partially separated shapes, and an automatic separation system collects the cut material and disposes of the waste.

Applications of Flexible Dies

- Specialized Equipment: Functional tapes cut by flexible dies can be applied to specialized equipment, resisting harsh climates and long-term wear. They can also be used on helmets and gloves.

- Medical Field: Used for bandages, wound dressings, diagnostic test strips, and adhesive components of medical devices.

- Industrial Machinery and Automotive Industry: Seal and gasket.

- Labels and Stickers Industry: Widely used for continuous forms, envelopes, custom labels of various shapes and sizes, stickers, barcodes, and security labels.

- Electronics Industry: Can cut panels, flexible printed circuits (FPC), RFID tags, insulators, and protective films.

- Packaging: Used for thin corrugated boards, paperboard packaging boxes, paper bags, and plastic bags.

Why Recommend Using Flexible Dies? 4 Major Reasons and Advantages

1. High Precision and Tight Tolerance

Flexible dies are particularly suitable for the die-cutting industry, where high precision and low tolerance are required. The CNC manufacturing process produces die edges with tolerance precision far exceeding traditional wooden dies, achieving a difference of more than tenfold.

2. Overcoming Small Angle Limitations and Seaming Issues

Flexible dies can overcome the limitations of die-cutting at small angles and the issues related to seaming, ensuring high-quality die-cutting.

3. Fast Production Speed

Flexible dies offer fast production speeds and high efficiency. They can be widely applied to various die-cutting needs, making them popular across different industries.

4. Kiss Cutting

Kiss cutting is a die-cutting technique where the blade only cuts through the top layer of material without penetrating entirely. This technique is commonly used for labels, stickers, decals, and other products with adhesive backings.

Recommended Flexible dies material:

Hung Shuh's steel plate

Hung Shuh Encyclopedia: Comparison of Rotary Die Cutting, Flatbed Die Cutting, and Laser Die Cutting

- Rotary Die Cutting: Uses cylindrical dies with sharp blades to cut materials. This process is suitable for high-speed, continuous production and can be used on various materials. Rotary dies are highly customizable, meeting clients' precision and shape requirements. Among the three methods, rotary die cutting is the fastest.

- Laser Die Cutting: Extremely precise and capable of handling complex designs and shapes. It uses laser beams to cut materials without requiring dies. Like rotary die cutting, laser die cutting is suitable for various materials. However, laser die cutting is slower than rotary die cutting. It is ideal for prototypes, small batch production with intricate details, and materials difficult to cut using other methods.

- Flatbed Die Cutting: Utilizes hydraulic presses and die-cutting blades to cut and shape materials. This method is suitable for various materials, especially those that are hard or thick, and offers broader applications. The highly customized die-cutting blades meet most market demands in terms of shape and size.

【Related articles】Steel Cutting Rules Guide: Advantages & FAQ