In accordance with the EU's implementation of the Personal Data Protection Act, we are committed to safeguarding your personal information and providing you control over it. We have updated and will regularly update our Privacy Policy to comply with this personal data protection law. Please refer to our latest Privacy Statement.

This website uses cookies to enhance your browsing experience. To learn more about how this website uses cookies, please click here.

Latest News

09.Jan.2025

Selected Articles

Thick Material and High Rule - Applications and Techniques

Thick Material and High Rule - Applications and Techniques

In modern manufacturing and processing industries, the demand for handling thick materials is growing rapidly. With advances in technology and increasing market requirements for high-quality products, techniques for processing and cutting thick materials have become crucial. Effectively handling thick materials and selecting the right tools and techniques is key to ensuring production efficiency and product quality. This guide introduces the concepts of Thick Material and High Rule, helping you understand the importance of selecting suitable die-cutting tools for various industrial applications.

What are Thick Material and High Rule?

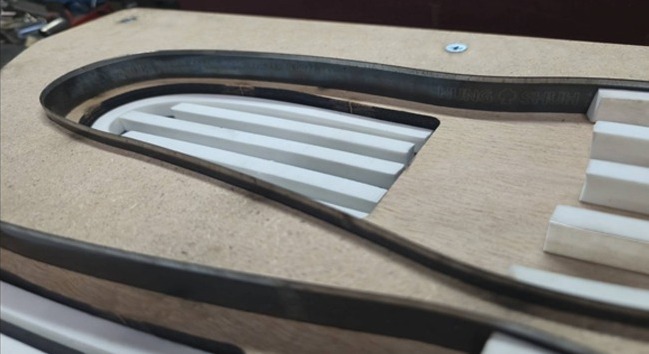

In the field of die-cutting, commonly used tool heights are typically 23.6mm or 23.8mm, suitable for cutting materials up to 2.5mm thick. When materials exceed 2.5mm, they are classified as "Thick Material." Cutting thick materials requires the use of a high rule to achieve smooth and precise cuts through the material.

Generally, High Rule refers to blades taller than 30mm, suitable for cutting materials such as acoustic foam, thick leather, EVA foam (like interlocking mats), industrial plastics, cork, fiberboard, and plywood used in furniture manufacturing.

To select the appropriate High Rule for die cutting, consider the following three aspects:

-

Material Features

Modern die-cutting blades come in various heights, thicknesses, and hardness levels. Select a High Rule based on the material’s characteristics and desired cut finish.

-

Select Quality Steel

High-quality steel blades not only produce clean cuts but also have a longer lifespan. Premium steel ensures durability and flexibility, resulting in superior cutting quality and longevity.

-

Ensure Quality

High-precision blades ensure stability and accuracy. Choose trusted, top-market brands for reliability and consistent performance.

Common Applications for High Rule in Thick Material Cutting

What industries benefit from High Rule cutting? Common applications include:| Material | Product Examples | Industries |

| Foam | EVA mats, PE foam (automotive parts, medical equipment) | Consumer goods, automotive, medical, electronics, aerospace, defense |

| eather | Bags, shoes, sofa upholstery | Consumer goods |

| Cork | Bottle stoppers, gaskets | Consumer goods, construction |

| Rubber | Gaskets, seals | Industrial applications |

| Fiberboard | MDF, HDF | Furniture, construction, interior design |

| Plywood | Ceiling, flooring, wall panels | Construction, interior design |

Alternative Methods for Cutting Thick Materials

Apart from die-cutting, other methods include:

| Method | Features | Suitable Materials |

| Laser Cutting | High precision; less efficient for very thick materials | Cardboard, plastic sheets, fiberboard, leather |

| Waterjet Cutting | Uses high-pressure water with abrasives; no heat deformation | Foam, plastic, rubber, fiberboard |

| CNC Milling | Processes complex, hard materials with high accuracy | Plywood, plastic, fiberboard, foam |

| Electric Leather Cutter | Specialized for thick, soft materials like leather | Leather, fabric |

| Manual Tool | Suitable for small-scale, low-precision tasks | Leather, foam, small plastic pieces |

High Rule die-cutting combines many advantages of these methods, offering speed, cost-efficiency, and versatility, making it a widely adopted solution in the industry.

Why Choose Hung Shuh for High Rule Solutions?

If you require thick material cutting or custom High Rule solutions, Hung Shuh offers five key advantages to meet your needs:

- Suitable for Various Thick Materials:

- High-Quality Steel for Enhanced Durability:

- Customization to Meet Specific Needs:

- Precision Manufacturing:

- High Market Share:

For any High Rule or die-cutting needs, please feel free to contact Hung Shuh. We are committed to delivering high-quality solutions for precise and efficient cutting.

Other

11

Sep.2024

Selected Articles

Thermoforming Die Cutting Guide and Applications

09

Aug.2024

Selected Articles

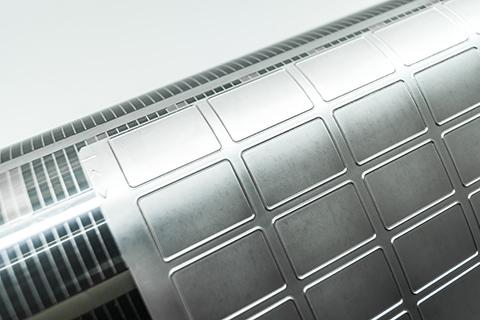

Flexible Dies & Rotary Die Cutters: Applications and Advantages

14

May.2024

Selected Articles