In accordance with the EU's implementation of the Personal Data Protection Act, we are committed to safeguarding your personal information and providing you control over it. We have updated and will regularly update our Privacy Policy to comply with this personal data protection law. Please refer to our latest Privacy Statement.

This website uses cookies to enhance your browsing experience. To learn more about how this website uses cookies, please click here.

Latest News

24.Jan.2024

Selected Articles

Steel Cutting Rules Guide: Advantages & FAQ

Discover what steel rule die cutting is, the application of cutting die, and why Hung Shuh is a renowned steel cutting rule manufacturer.

Steel Cutting Rules Guide: Advantages & FAQ

If steel rule die cutting confuses you, this article can help. Here, we explore what steel rule die cutting is, the types of steel cutting rules available, and their advantages. Gain a quick understanding of steel rule die cutting and discover its superiority compared to other cutting techniques. Explore the materials that can be effectively cut using this method and get insights into common questions surrounding steel rule die cutting. This ultimate guide aims to provide clarity on steel cutting rules, ensuring you have a comprehensive grasp of the subject.What is Steel Rule Die Cutting?

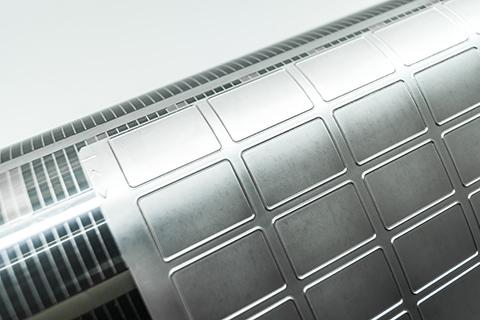

Steel rule die cutting is a specialized technique used for cutting materials into precise shapes using a die, which is a specialized tool. It functions similarly to a paper hole puncher, creating various shapes by cutting through different types of materials. The versatility of steel rule die cutting extends to materials such as corrugated paper, cardboard, cardstock, food containers, foam, plastic thermoforming, plastic sheets, cushioning materials, fabric, industrial gaskets, and electronic and semiconductor-related materials.To perform steel rule die cutting, the cutting die needs to be installed on a die template, and a professional mechanical device is employed for the cutting process through stamping. In comparison to other cutting methods like laser cutting, stamping, and wire cutting, steel rule die cutting stands out as a more economical option.

What are the Advantages of Steel Rule Die Cutting?

Compared to other cutting methods, steel rule die cutting stands out as an efficient, precise, and cost-effective cutting tool widely used across various industries. It can meet cutting requirements for different materials and shapes, providing reliable solutions in the manufacturing process.Specifically, the advantages of steel rule die cutting can be summarized as follows:

- Precision: Steel rule die cutting ensures consistent shapes with every cut.

- Flexibility: It is suitable for a wide range of soft and semi-rigid materials, allowing flexibility in addressing cutting needs for different materials.

- Efficiency: When coupled with professional machinery, steel rule die cutting operates efficiently, enhancing production efficiency.

- Cost-effectiveness: Compared to the molds and fixture fee of wire cutting, laser and stamping, can reduce a lot of cost, and the die-making time is short, contributing to cost savings in production.

- Clean and Neat Cuts: Steel rule die cutting ensures clean a surface, less burr, dust, and angel hair.

- Arrangement on the Cutting Die: A single die can accommodate multiple cavities, effectively utilizing space and minimizing raw material waste, thereby maximizing production efficiency.

What Materials can be Cut with a Steel Rule Die?

The application range of steel rule die cutting is quite extensive, catering to the cutting needs of various materials. Common materials include:- Blister or disposable plastic food container: OPS (oriented polystyrene), PP (polypropylene), PS (polystyrene), PET (polyethylene terephthalate).

- Paper food container

- Foam, sponge

- Felt

- Leather

- Thin films

- Conductive fabric

- PTP (Press-Through Packaging) blister

- Corrugated box

- Graphene textiles or gaskets

- Puzzles

- Cushion packaging

- Mobile phone screen protectors

- Flexible printed circuit boards

- Semiconductor-related industries

Why choose Hung Shuh for Steel Cutting Rules?

Hung Shuh is a globally renowned leader in steel-cutting rule manufacturing, known for the quality and durability of its products. With a presence in nearly 100 countries, Hung Shuh has earned a worldwide reputation across various industries.

The advantages of Hung Shuh's products include:

1. Over 50 years of rich experience:

With over 50 years of experience in the steel market, Hung Shuh possesses extensive industry expertise in the production of steel cutting rules, ensuring the delivery of high-quality products to customers.2. Mastery of the highest quality steel:

Recognized as the largest overseas agent of "NIPPON STEEL," the world's second-largest steelmaker based in Japan, Hung Shuh has abundant inventory to instantly meet diverse steel requirements, guaranteeing the use of top-quality materials.3. Continuous adoption of advanced equipment:

Hung Shuh continually invests in expanding and updating its equipment, introducing the latest machinery and technology from industrial advanced countries such as Germany, Austria, and Japan. This commitment ensures that Hung Shuh remains at the forefront of both hardware and software.4. 100% customization capability:

Possessing comprehensive production technology and industry standards mastery, Hung Shuh can meet customer requirements for various product specifications.For details on our customization capabilities, please contact us.

5. Strong R&D and quality assurance teams:

With over 50 years of production experience, Hung Shuh boasts a robust research and development (R&D) and quality assurance team. However, the company doesn't rest on its laurels; it consistently enhances technical capabilities by engaging external professional consultants.Combining these advantages, Hung Shuh excels in utilizing the highest quality steel. With over 50 years of production experience, coupled with cutting-edge equipment and technology, it produces the finest steel cutting rules. Furthermore, Hung Shuh can tailor its products to meet different custom specifications, taking pride in its strong R&D and quality assurance teams, which contribute to continuous improvements in technical capabilities.

Hung Shuh believes in offering you the best product. The company's commitment involves not just providing customization but delivering a cutting-edge advantage. The crafted steel cutting rules are precisely tailored to meet your needs, ensuring seamless integration with both cutting specifications and machine requirements. It's more than just customization; it's a bespoke solution designed to enhance equipment performance and streamline cutting processes.

FAQ about Steel Cutting Rules

Q: How are steel cutting rules manufactured?

The formation process of Hung Shuh's steel cutting rules is highly intricate. Initially, suitable steel strips are selected based on customer requirements, and divided into appropriate widths for tip formation. The tip is then shaped to the specified angle through grinding, followed by heat treatment (quenching) to enhance tip strength. Utilizing various professional techniques, Hung Shuh meticulously crafts high-quality steel cutting rules.Q: How do I maintain a steel cutting rule?

When delivered, steel cutting rules possess the sharpest tips. It is recommended to start with lower machine pressure during initial use and ensure the horizontal alignment of the die and base plate. Proper adjustments can slow down tip wear. As the tip naturally wears over time, machine pressure can be gradually increased during subsequent use. Additionally, we recommend using a sponge on the die to enhance cutting quality, prevent issues related to paper feeding, paper debris, or incomplete cuts due to increased machine pressure, and avoid accelerating overall wear and tear of the steel cutting rule.The suggested replacement time for a steel cutting rule is when, despite confirming the horizontal alignment of the die and machine and making appropriate adjustments, issues such as incomplete cuts or the generation of paper debris persist. At this point, the tool may have suffered damage, indicating the need for replacement. Even when used correctly, steel cutting rules are consumable items that require periodic replacement.

Q: How to choose the right steel cutting rule? What are the different types available?

Hung Shuh's steel cutting rules can fulfill almost 100% of cutting material requirements in the market. Tailored to different cutting needs, Hung Shuh offers various specifications of steel cutting rules, such as cutting knives suitable for the paper industry, straight-edge grinding tools for cardstock, side bevel knives for straight-cut surfaces, high knives for various cutting heights, tobacco knives with over two million cutting cycles, and finely ground knives for challenging cutting materials. Our sales team can provide optimal recommendations based on customer needs, ensuring the best user experience.For more detailed specifications of Hung Shuh steel cutting rules, you can refer to the Cutting Rules product page on our website.

Other

09

Jan.2025

Selected Articles

Thick Material and High Rule - Applications and Techniques

11

Sep.2024

Selected Articles

Thermoforming Die Cutting Guide and Applications

09

Aug.2024

Selected Articles