In accordance with the EU's implementation of the Personal Data Protection Act, we are committed to safeguarding your personal information and providing you control over it. We have updated and will regularly update our Privacy Policy to comply with this personal data protection law. Please refer to our latest Privacy Statement.

This website uses cookies to enhance your browsing experience. To learn more about how this website uses cookies, please click here.

HOME

Chromium Molybdenum Steel

Asked Questions

Chromium Molybdenum Steel

1.What is chromium-molybdenum steel ?+

Chromium-molybdenum steel is an alloy steel that contains a higher proportion of chromium and molybdenum elements. The addition of chromium and molybdenum can significantly enhance the mechanical properties and corrosion resistance of the steel, making chromium-molybdenum steel widely used in various application fields.

2.Pneumatic tools require durable materials and processes. What are the commonly used steel ?+

Pneumatic tools are tools powered by compressed air and are typically made from durable materials capable of withstanding prolonged and high-load usage. Commonly used steel grades include SK85 and 1085 steel.

3.What is the application range of chromium-molybdenum steel ?+

鉻鉬鋼應用舉例

-

Automotive IndustryAutomotive Industry: Chromium-molybdenum steel is used in the automotive manufacturing for producing engine components, steering parts, and chassis assemblies. Its high strength and toughness enable automotive parts to withstand high loads and impacts, while also providing good wear resistance and fatigue resistance.

-

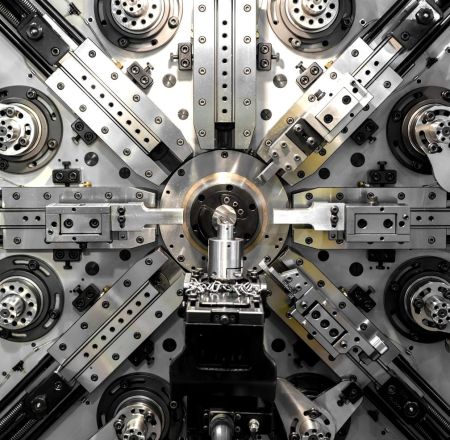

Machinery Manufacturing Industr

Chromium-molybdenum steel is commonly used in the manufacturing of machinery equipment and tools, such as bearings, gears, and cutting tools. Its high hardness, strength, and wear resistance make it suitable for applications that require high loads and durability. -

Components of waterborne vehicles

Components of waterborne vehicles, subjected to prolonged navigation and vibration, require excellent fatigue resistance to prevent component fracture and failure. These parts need to possess sufficient strength and toughness to ensure the stability and safety of the vessel's structure. Special material selection, design, and manufacturing processes can enhance the fatigue life of these components. Commonly used steel types include SCM415 and SCM435.

4.For chain drive components, which steel is commonly used ?+

Chain is a common mechanical transmission component, usually made from high-strength steel, capable of withstanding significant tensile forces and torques. It is suitable for high-load and high-strength transmission systems. Commonly used steel types include chromium-molybdenum steel and chromium steel products.

5.What are the characteristics of Watercraft and commonly used steel ?+

Shipbuilding Industry: Chromium-molybdenum steel is commonly used in the fabrication of mechanical components for waterborne vehicles. These components need to possess sufficient strength and toughness to ensure the stability and safety of the vessel's structure.

6.What are the features of seat belt components ?+