In accordance with the EU's implementation of the Personal Data Protection Act, we are committed to safeguarding your personal information and providing you control over it. We have updated and will regularly update our Privacy Policy to comply with this personal data protection law. Please refer to our latest Privacy Statement.

This website uses cookies to enhance your browsing experience. To learn more about how this website uses cookies, please click here.

HOME

Others

Asked Questions

Others

1.Hung Shuh's materials are sourced from Nippon Steel in Japan.+

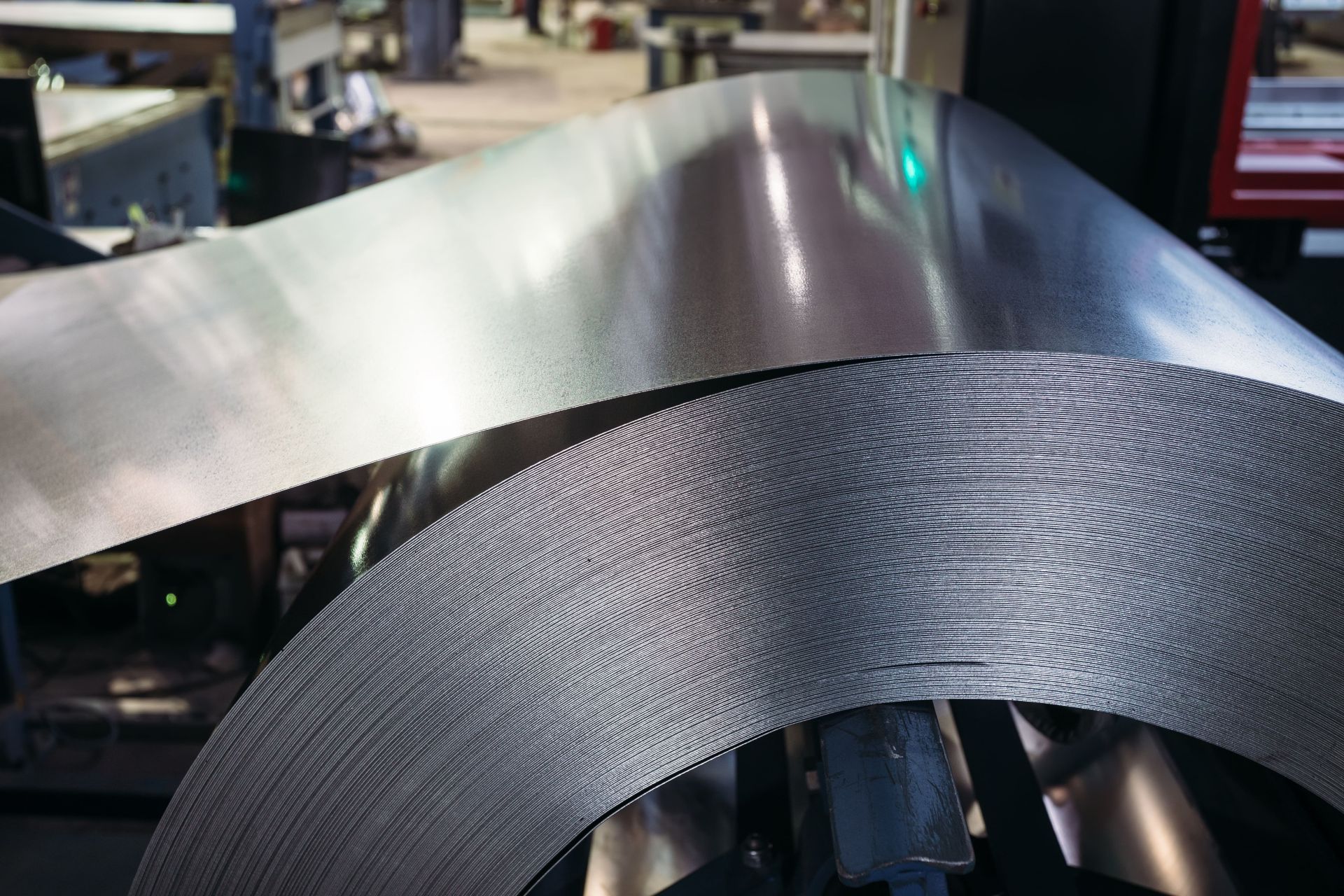

Japan is one of the world's major steel-producing countries, home to several renowned steel manufacturing companies, with Nippon Steel Corporation being the most prominent. Nippon Steel Corporation is one of Japan's largest steel manufacturers and ranks among the world's largest steel producers. The company is known for its high-quality and reliable products that adhere to strict international standards and customer requirements. With a focus on quality control and management, Nippon Steel is recognized for its high production capacity, technological leadership, diverse product lines, and quality reliability. The company is committed to sustainable development and holds a significant market share in the international market.

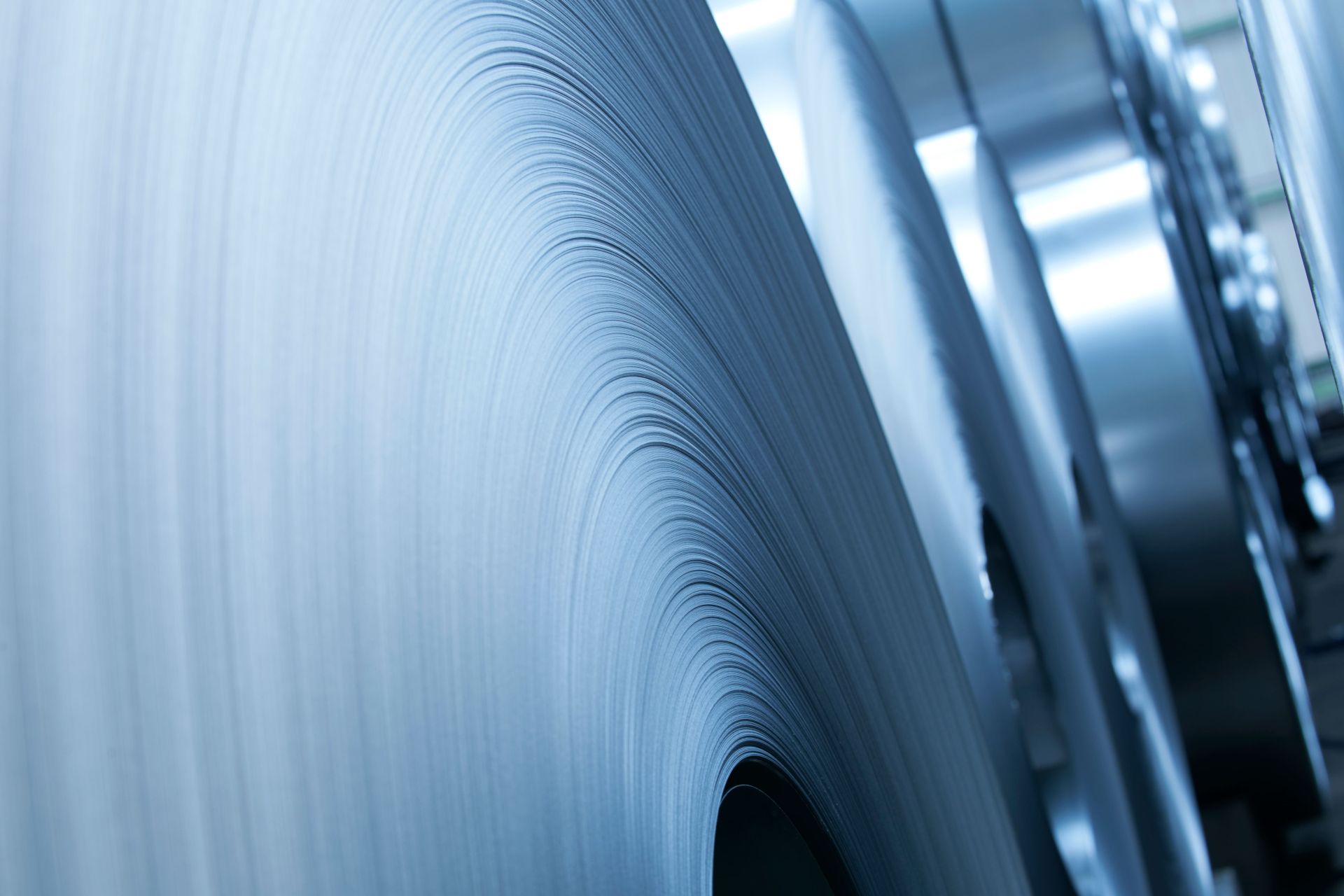

2.We possess the largest domestic heat treatment equipment for steel manufacturing.+

The widest heat treatment steel strip equipment domestically is held by Hongshu. Currently, they possess a 400mm-wide heat treatment facility to meet the requirements of customers seeking wide plate designs for their products.

3.Colored Surface Grinding Choices?+

In addition to our excellent heat treatment abilities, we also have colored steel strip options, providing you with more than just a single choice.

-

Polished White

For those interested, please feel free to contact us. -

Polished Golden

For those interested, please feel free to contact us. -

Polished Blue

For those interested, please feel free to contact us.

4.White surface can be selected in different ways?+

Polishing products

Textures of different thicknesses can be customized according to customer requirements

5.Trimming process is a method used in manufacturing or machining process, what are its main advantages?+

The main benefits of the edge trimming process are as follows:

The main benefits of the edge trimming process are as follows:

1. Appearance: The edge trimming process can remove irregular edges or burrs from materials or products, making their appearance smoother, neater, and more precise. This can enhance the overall aesthetics of the product, making it more attractive and meeting high-quality visual standards.

2. Safety: Irregular edges or burrs can pose a danger to users, such as the risk of cuts or punctures. The edge trimming process can eliminate these potential hazards, increase user safety, and reduce the risk of accidents and injuries.

3Functionality: The edge trimming process can improve the functionality of products. For example, in electronics manufacturing, the edge trimming process can ensure precise fitting between components, enhancing product performance and reliability.

4. Precision: The edge trimming process can provide highly accurate finishing results. Whether done manually or with machinery, edge trimming can achieve precise control and adjustments to ensure compliance with required dimensions and appearance standards.

5. Automation: The edge trimming process can be integrated with automation technology for efficient production. Machine trimming can significantly increase manufacturing speed and capacity while reducing labor costs and the risk of human errors.

2. Safety: Irregular edges or burrs can pose a danger to users, such as the risk of cuts or punctures. The edge trimming process can eliminate these potential hazards, increase user safety, and reduce the risk of accidents and injuries.

3Functionality: The edge trimming process can improve the functionality of products. For example, in electronics manufacturing, the edge trimming process can ensure precise fitting between components, enhancing product performance and reliability.

4. Precision: The edge trimming process can provide highly accurate finishing results. Whether done manually or with machinery, edge trimming can achieve precise control and adjustments to ensure compliance with required dimensions and appearance standards.

5. Automation: The edge trimming process can be integrated with automation technology for efficient production. Machine trimming can significantly increase manufacturing speed and capacity while reducing labor costs and the risk of human errors.

In summary, the edge trimming process offers advantages such as improved aesthetics, safety, functionality, and precision of products, while also enabling automated production to enhance efficiency and quality.

6.What is the density ratio between carbon steel and carbon tool steel?+

about 7.85 g/cm³.

7.What is the minimum order quantity for raw materials?+