In accordance with the EU's implementation of the Personal Data Protection Act, we are committed to safeguarding your personal information and providing you control over it. We have updated and will regularly update our Privacy Policy to comply with this personal data protection law. Please refer to our latest Privacy Statement.

This website uses cookies to enhance your browsing experience. To learn more about how this website uses cookies, please click here.

Asked Questions

ALL

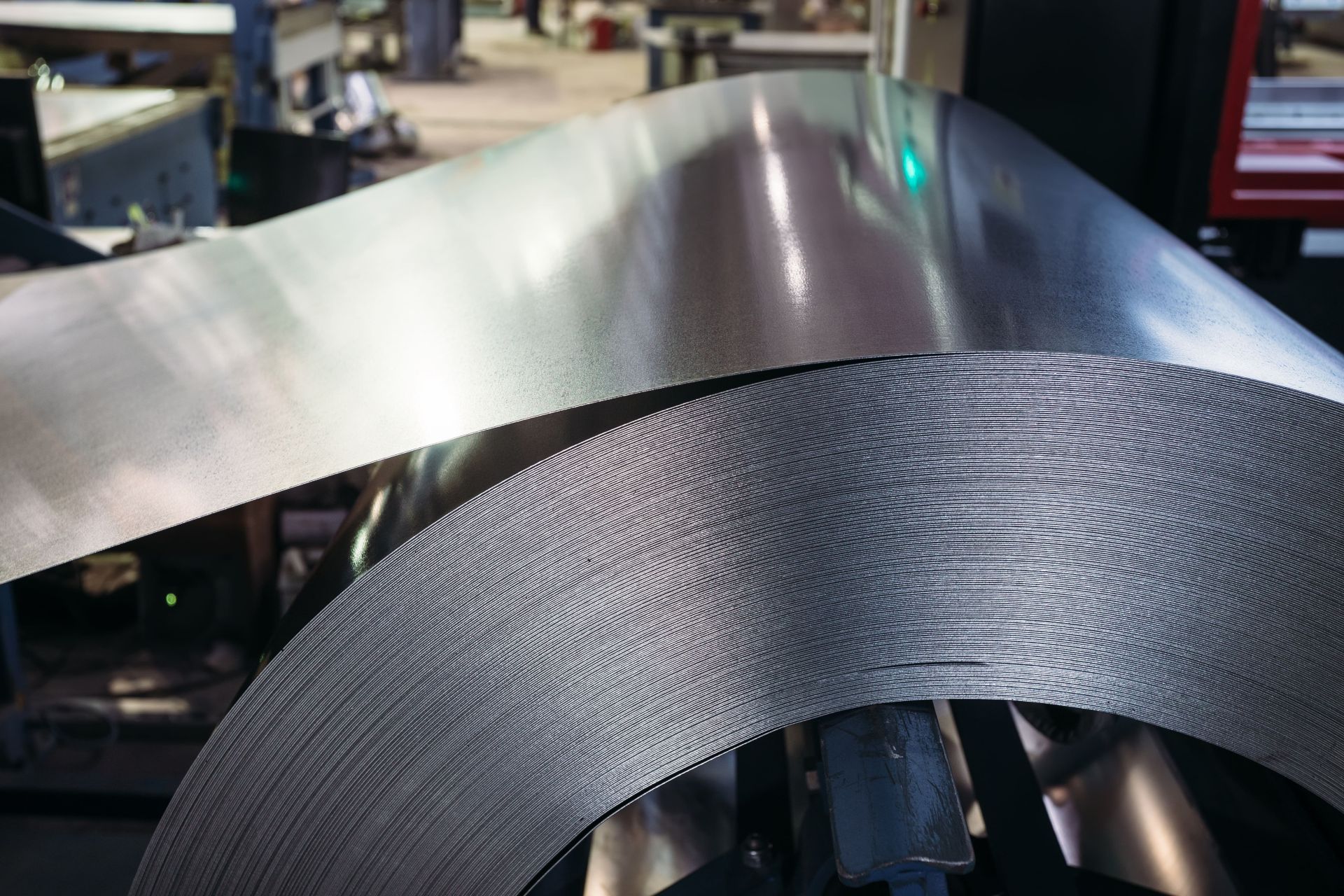

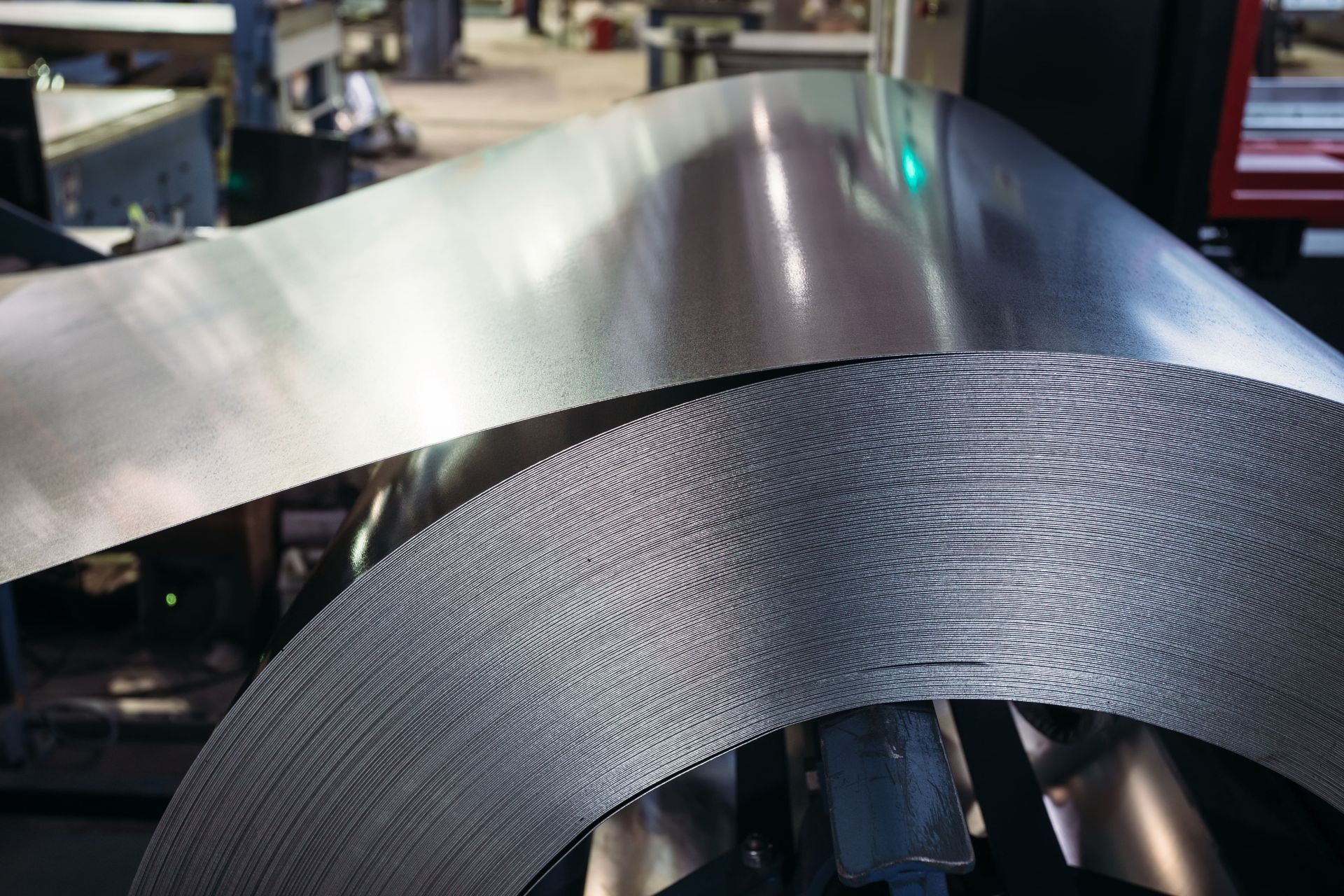

1.Hung Shuh's materials are sourced from Nippon Steel in Japan.+

Japan is one of the world's major steel-producing countries, home to several renowned steel manufacturing companies, with Nippon Steel Corporation being the most prominent. Nippon Steel Corporation is one of Japan's largest steel manufacturers and ranks among the world's largest steel producers. The company is known for its high-quality and reliable products that adhere to strict international standards and customer requirements. With a focus on quality control and management, Nippon Steel is recognized for its high production capacity, technological leadership, diverse product lines, and quality reliability. The company is committed to sustainable development and holds a significant market share in the international market.

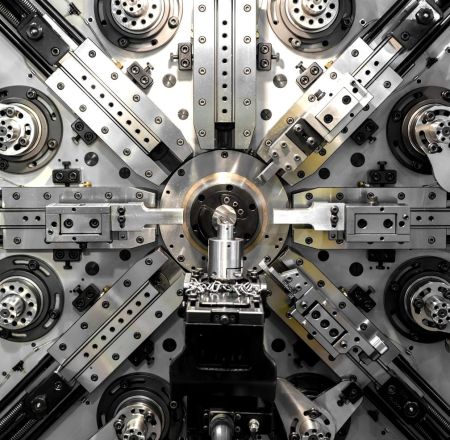

2.We possess the largest domestic heat treatment equipment for steel manufacturing.+

The widest heat treatment steel strip equipment domestically is held by Hongshu. Currently, they possess a 400mm-wide heat treatment facility to meet the requirements of customers seeking wide plate designs for their products.

3.Colored Surface Grinding Choices?+

In addition to our excellent heat treatment abilities, we also have colored steel strip options, providing you with more than just a single choice.

-

Polished White

For those interested, please feel free to contact us. -

Polished Golden

For those interested, please feel free to contact us. -

Polished Blue

For those interested, please feel free to contact us.

4.White surface can be selected in different ways?+

Polishing products

Textures of different thicknesses can be customized according to customer requirements

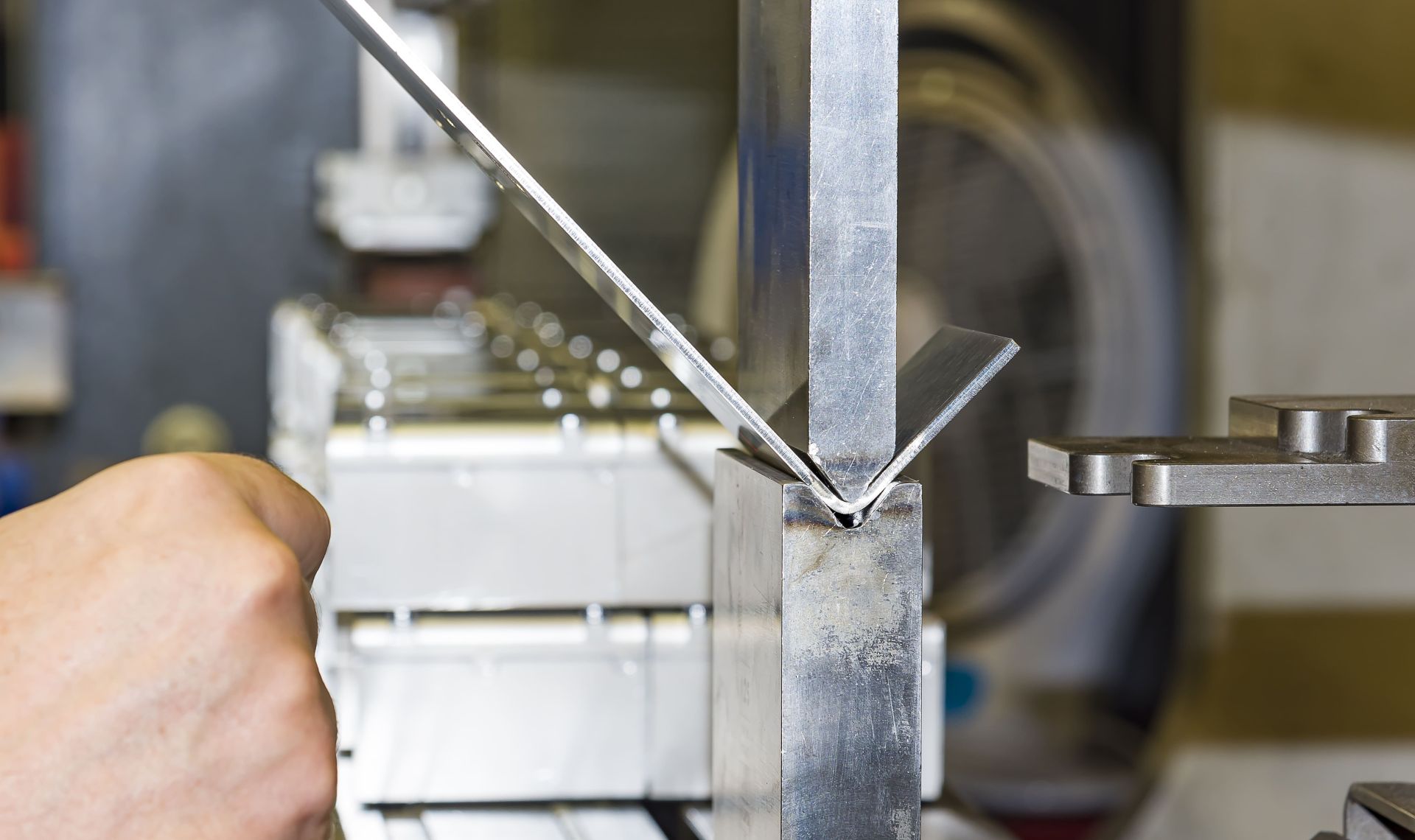

5.Trimming process is a method used in manufacturing or machining process, what are its main advantages?+

The main benefits of the edge trimming process are as follows:

The main benefits of the edge trimming process are as follows:

1. Appearance: The edge trimming process can remove irregular edges or burrs from materials or products, making their appearance smoother, neater, and more precise. This can enhance the overall aesthetics of the product, making it more attractive and meeting high-quality visual standards.

2. Safety: Irregular edges or burrs can pose a danger to users, such as the risk of cuts or punctures. The edge trimming process can eliminate these potential hazards, increase user safety, and reduce the risk of accidents and injuries.

3Functionality: The edge trimming process can improve the functionality of products. For example, in electronics manufacturing, the edge trimming process can ensure precise fitting between components, enhancing product performance and reliability.

4. Precision: The edge trimming process can provide highly accurate finishing results. Whether done manually or with machinery, edge trimming can achieve precise control and adjustments to ensure compliance with required dimensions and appearance standards.

5. Automation: The edge trimming process can be integrated with automation technology for efficient production. Machine trimming can significantly increase manufacturing speed and capacity while reducing labor costs and the risk of human errors.

2. Safety: Irregular edges or burrs can pose a danger to users, such as the risk of cuts or punctures. The edge trimming process can eliminate these potential hazards, increase user safety, and reduce the risk of accidents and injuries.

3Functionality: The edge trimming process can improve the functionality of products. For example, in electronics manufacturing, the edge trimming process can ensure precise fitting between components, enhancing product performance and reliability.

4. Precision: The edge trimming process can provide highly accurate finishing results. Whether done manually or with machinery, edge trimming can achieve precise control and adjustments to ensure compliance with required dimensions and appearance standards.

5. Automation: The edge trimming process can be integrated with automation technology for efficient production. Machine trimming can significantly increase manufacturing speed and capacity while reducing labor costs and the risk of human errors.

In summary, the edge trimming process offers advantages such as improved aesthetics, safety, functionality, and precision of products, while also enabling automated production to enhance efficiency and quality.

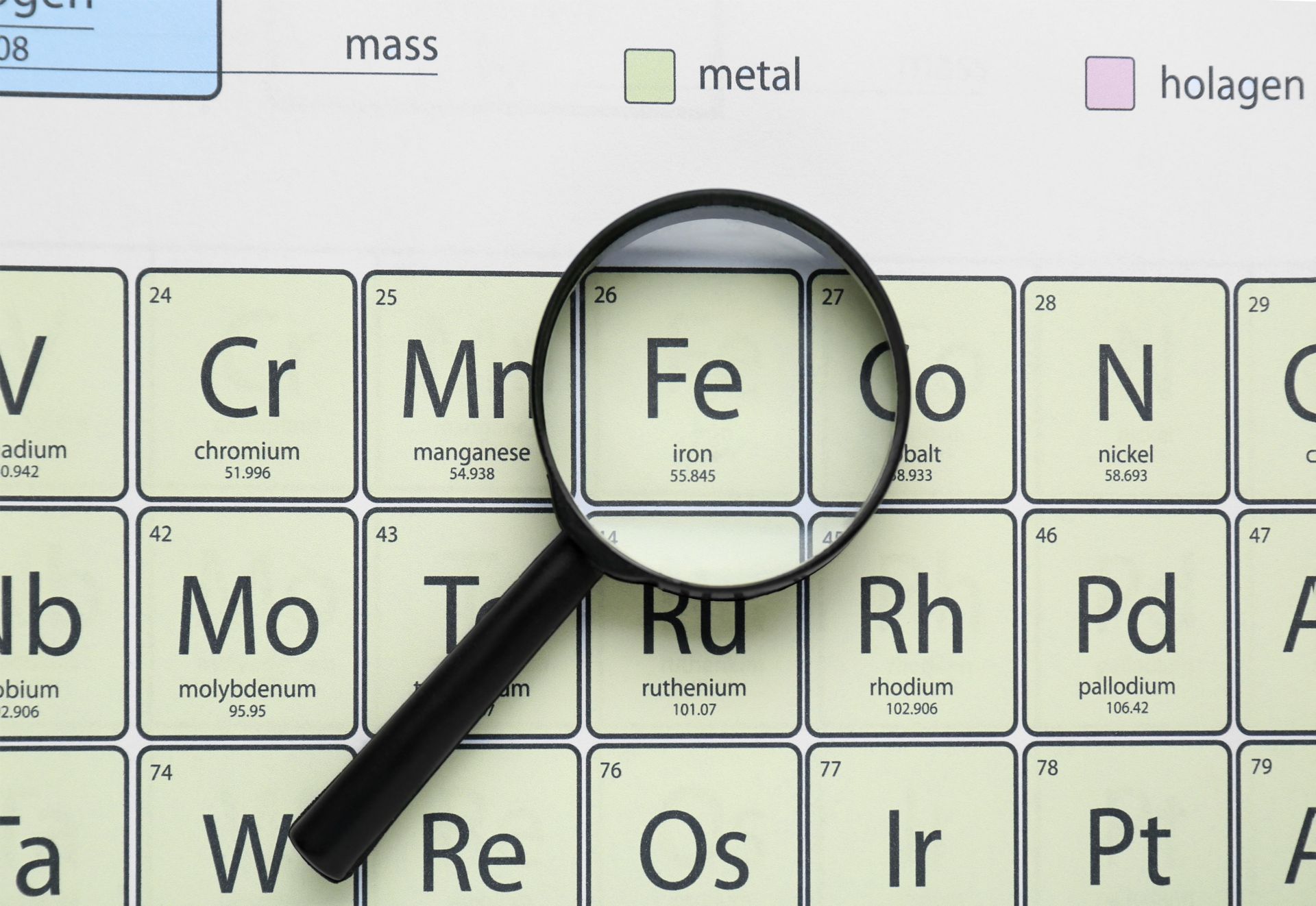

6.What is the density ratio between carbon steel and carbon tool steel?+

about 7.85 g/cm³.

7.What is the minimum order quantity for raw materials?+

For the futures segment, the minimum order quantity (MOQ) is 15 tons. For general raw material small batch orders, the weight is calculated by multiplying the basic width by 3 to determine the weight of one coil of raw material. Whenever possible, MOQ is encouraged to be set at one or more coils as the unit.

8.What is chromium-molybdenum steel ?+

Chromium-molybdenum steel is an alloy steel that contains a higher proportion of chromium and molybdenum elements. The addition of chromium and molybdenum can significantly enhance the mechanical properties and corrosion resistance of the steel, making chromium-molybdenum steel widely used in various application fields.

9.Why choose carbon steel ?+

Carbon steel is a high-strength material with excellent tensile and compressive strength. This allows hardware components manufactured from carbon steel to withstand significant loads, enhancing the durability of the products.

10.Pneumatic tools require durable materials and processes. What are the commonly used steel ?+

Pneumatic tools are tools powered by compressed air and are typically made from durable materials capable of withstanding prolonged and high-load usage. Commonly used steel grades include SK85 and 1085 steel.

11.What are the applications of alloy steel ?+

Alloy steel exhibits excellent mechanical properties, heat resistance, corrosion resistance, and wear resistance, making it widely used in various fields such as tool manufacturing, automotive production, aerospace, and more.

12.Which steel types of carbon tool steel are used for circular saws ?+

Circular saws possess powerful cutting capabilities and are often paired with different types of saw blades to meet the cutting requirements of various materials. Circular saws typically have the ability for high-speed cutting, allowing for efficient handling of large workloads and enhancing production efficiency. Commonly used steel types for circular saw blades include SK85, SK95, 1085 steel, SKS51, and SKS5. These steel types are among the most frequently utilized options for users of high-carbon steel and suppliers of carbon tool steel.

13.What is the application range of chromium-molybdenum steel ?+

鉻鉬鋼應用舉例

-

Automotive IndustryAutomotive Industry: Chromium-molybdenum steel is used in the automotive manufacturing for producing engine components, steering parts, and chassis assemblies. Its high strength and toughness enable automotive parts to withstand high loads and impacts, while also providing good wear resistance and fatigue resistance.

-

Machinery Manufacturing Industr

Chromium-molybdenum steel is commonly used in the manufacturing of machinery equipment and tools, such as bearings, gears, and cutting tools. Its high hardness, strength, and wear resistance make it suitable for applications that require high loads and durability. -

Components of waterborne vehicles

Components of waterborne vehicles, subjected to prolonged navigation and vibration, require excellent fatigue resistance to prevent component fracture and failure. These parts need to possess sufficient strength and toughness to ensure the stability and safety of the vessel's structure. Special material selection, design, and manufacturing processes can enhance the fatigue life of these components. Commonly used steel types include SCM415 and SCM435.

14.For chain drive components, which steel is commonly used ?+

Chain is a common mechanical transmission component, usually made from high-strength steel, capable of withstanding significant tensile forces and torques. It is suitable for high-load and high-strength transmission systems. Commonly used steel types include chromium-molybdenum steel and chromium steel products.

15.What are the characteristics of Watercraft and commonly used steel ?+

Shipbuilding Industry: Chromium-molybdenum steel is commonly used in the fabrication of mechanical components for waterborne vehicles. These components need to possess sufficient strength and toughness to ensure the stability and safety of the vessel's structure.

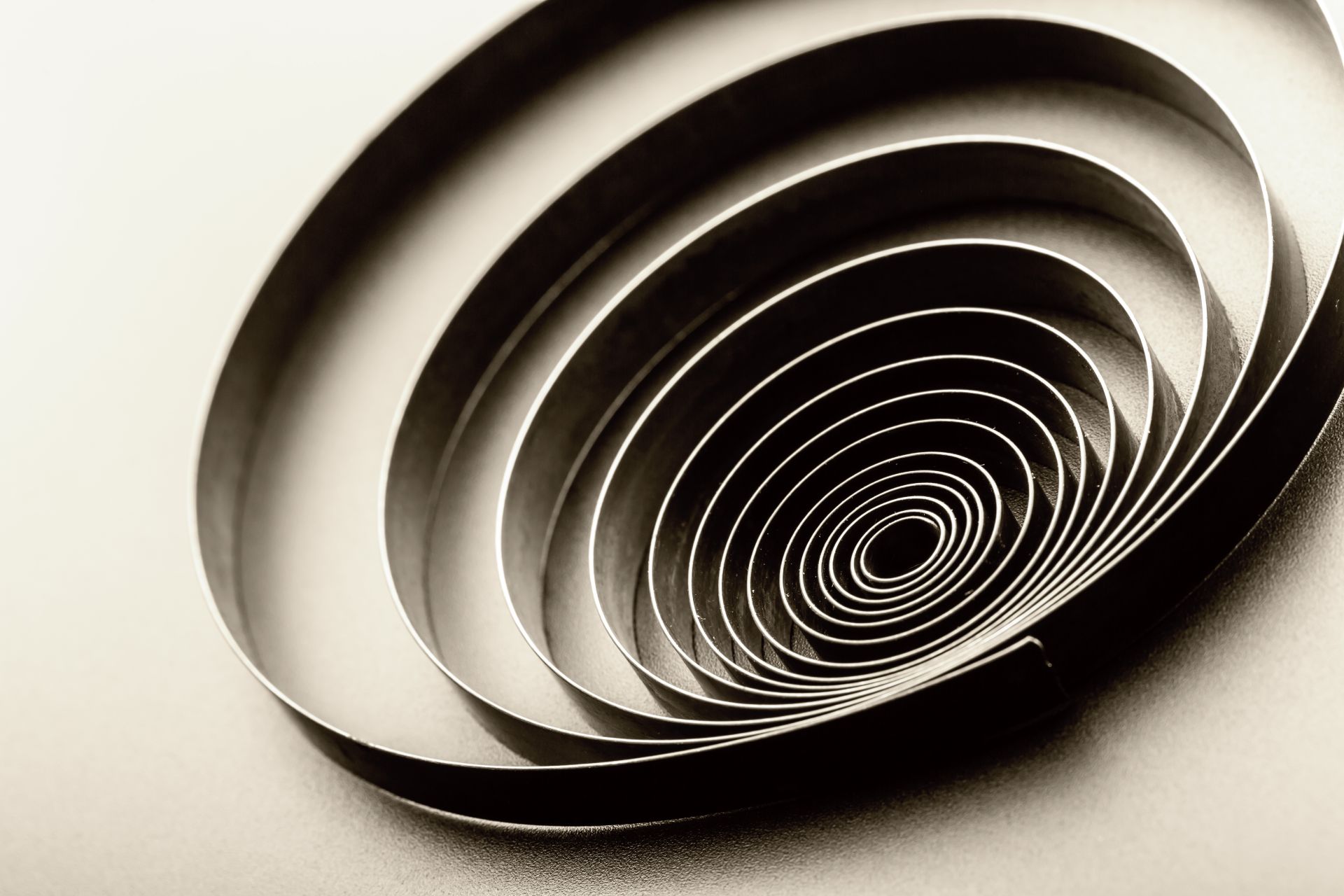

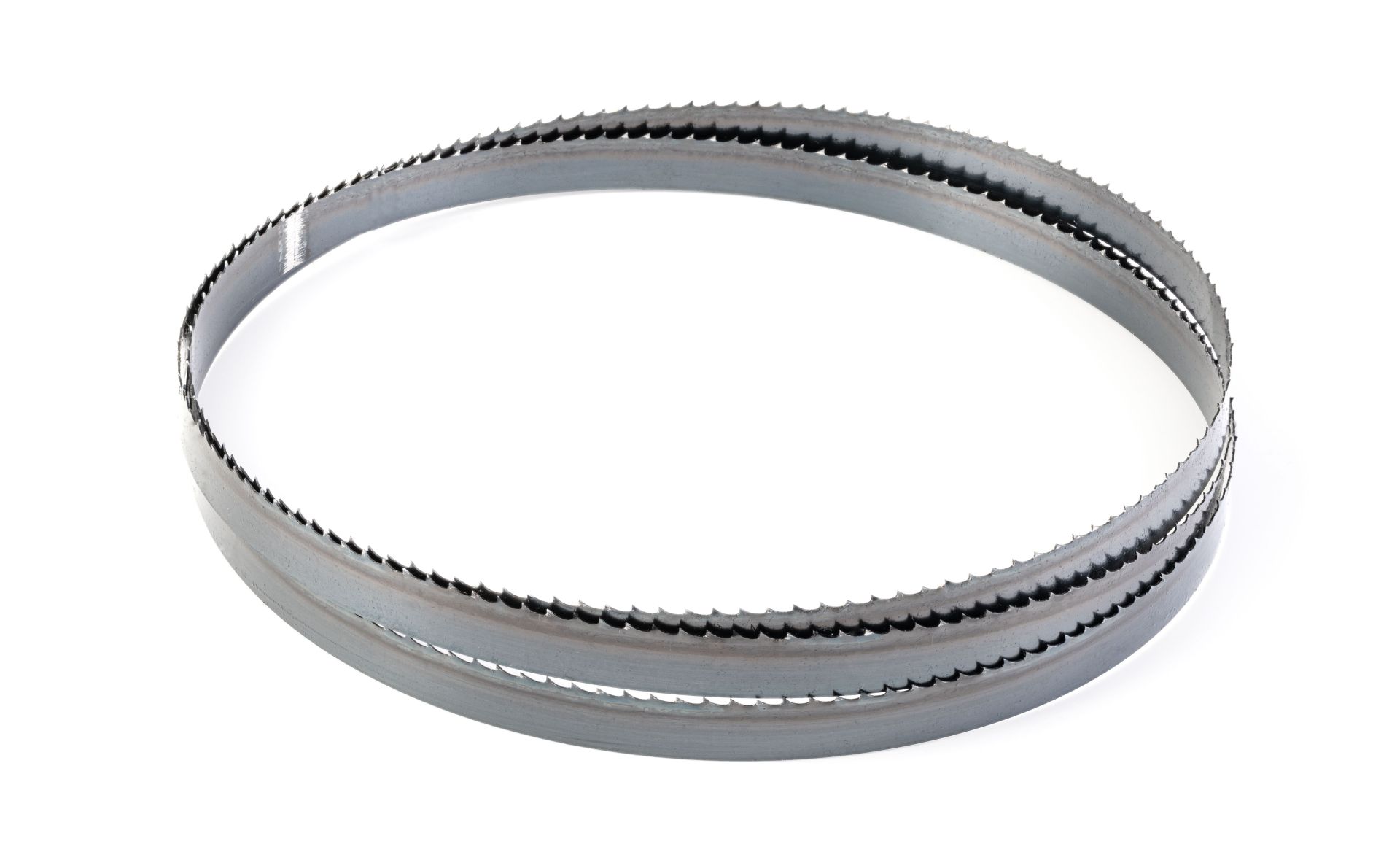

16.What are the commonly used materials for band saw coils with excellent cutting ability ?+

Band saws possess excellent cutting capability and can be used to cut various materials. The cutting process involves using a continuous blade in a belt-like tool, allowing for precise straight or curved cuts. Commonly used materials for band saw steel coils include carbon tool steel and alloy steel products, often optimized through heat treatment processes. Commonly used steel grades include SK85, SK95, 1085 steel, and the SKS series

17.What are the features of seat belt components ?+

A seat belt is a safety device used to protect people in vehicles or other modes of transportation. It requires a locking mechanism, impact energy absorption, and pre-tensioning features, necessitating stable materials to enhance your product. The most commonly used steel grades are S50C, S55C, S65C, and 1065 steel.

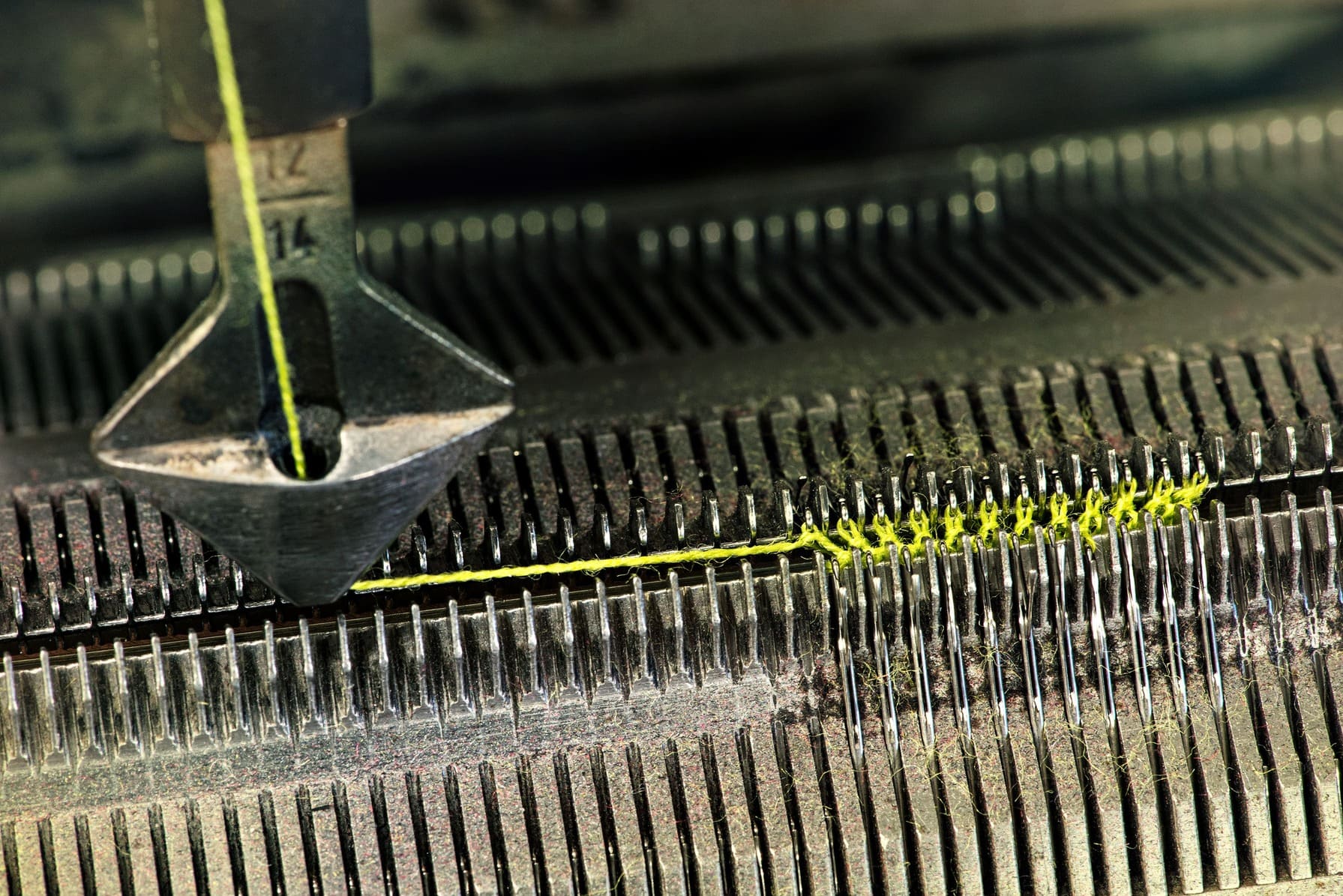

18.What is the commonly used steel grades for knitting parts ?+

Knitted parts typically possess specific fabric structures; high-quality knitted parts often exhibit good durability and precise accuracy. Therefore, manufacturing requires high-quality materials for producing machine components. The most commonly used steel grades are SK95, SK85, and 1085 steel.

19.What are the commonly used materials for band saw steel coils with excellent cutting capability ?+

Band saws possess excellent cutting capability and can be used to cut various materials. The cutting process involves using a continuous blade in a belt-like tool, allowing for precise straight or curved cuts. Commonly used materials for band saw steel coils include carbon tool steel and alloy steel products, often optimized through heat treatment processes. Commonly used steel grades include SK85, SK95, 1085 steel, and the SKS series

20.Why use carbon steel for wiper parts ?+

Wiper parts require an appropriate level of elasticity and pressure to ensure that the blades adhere tightly to the windshield surface and apply pressure evenly. Carbon steel possesses excellent strength and hardness, allowing it to withstand high levels of stress and load, while also meeting processing requirements. It is the optimal choice for both carbon steel suppliers and cold-rolled steel suppliers.

21.Characteristics and steel grades for Hand tools' applications ?+

Hand tools are tools held and operated by people, requiring characteristics such as durability, functionality, comfort, precision, accuracy, safety, and maintainability. Commonly used steel grades include S50C, S65C, SK85, 1065, 1085, SCM series, and SKS series.

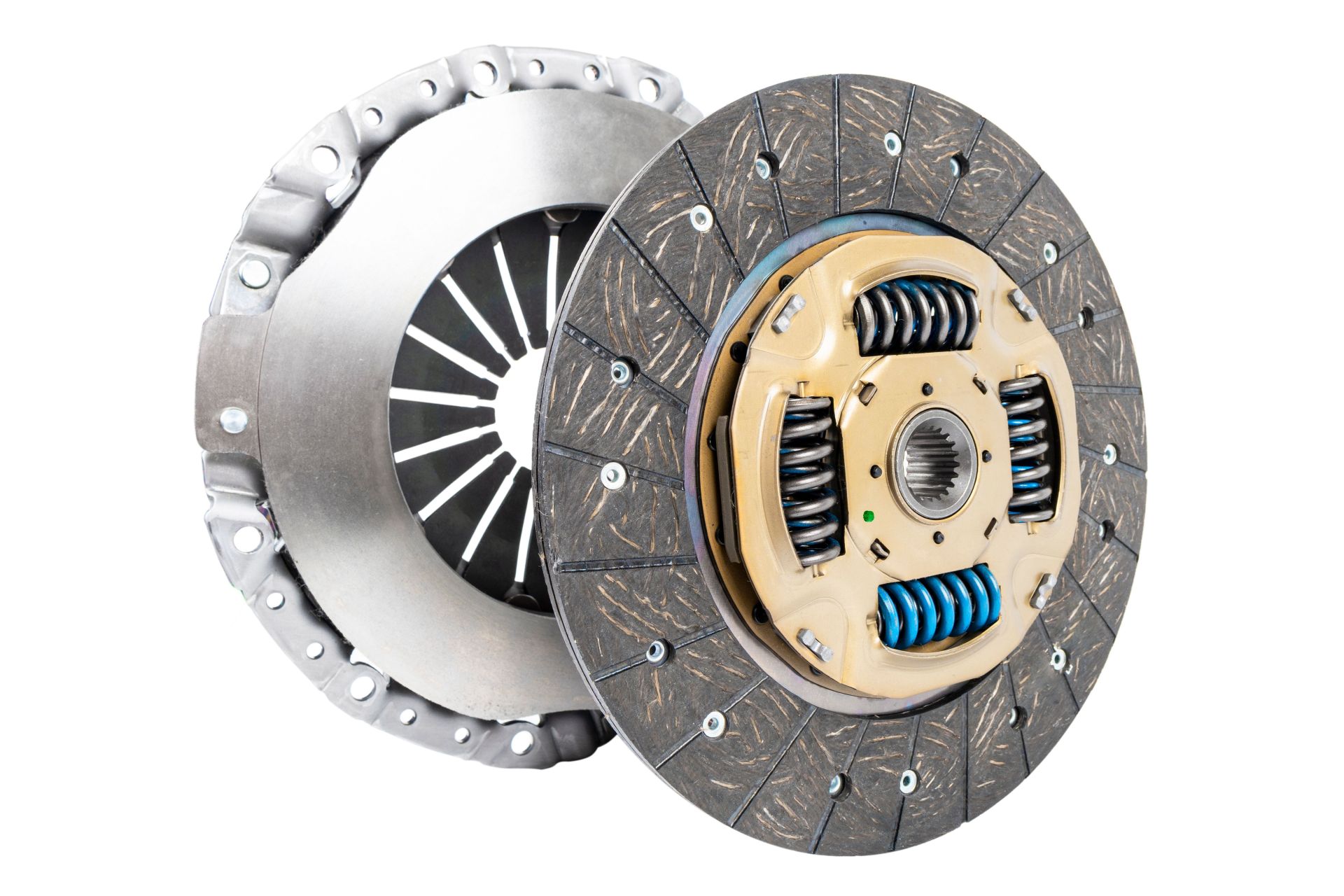

22.Is carbon steel suitable for clutch parts? What are the features of seat belt components ?+

A clutch is a device used to control power transmission and requires wear resistance and thermal stability. Therefore, using Nippon Steel's carbon steel or carbon tool steel products, along with advanced heat treatment equipment, can optimize your products. Commonly used steel grades are S50C, S65C, SK85, 1065, and 1085.

23.What is the density ratio of alloy steel ?+

The density range of alloy steel is relatively wide, typically between 7.7 g/cm³ and 8.1 g/cm³, depending on the alloying elements and their content added to the alloy steel.

24.What are the characteristics and commonly used steel grades for hand saw ?+

A hand saw is a handheld tool used for manually cutting materials such as wood, metal, plastic, and more. High-quality hand saws are typically crafted from durable materials, offering excellent durability and resistance to wear. They often utilize heat-treated steel strip products made from carbon tool steel, which has undergone a heat treatment process to enhance its properties.

25.What is "Cutting Rule"?+

"Cutting Rule" is a special knife, most of which are used in paper, leather, plastic…. The cutting action, in order to create a specific shape and pattern, the characteristics of the three elements of the Thomson knife need to have flexibility, sharpness and durability to be called a good Cutting Rule, which has been the key.

26.What is a "Cutting-Die" for?+

Generally speaking, wooden die is the most frequently-used Cutting Die, which is made by wooden board, cutting rule, and ejection materials. Cutting Die is applied when substrates need to be cut & shaped

27.What is "Die Cutting"?+

"Die Cutting" is processed with Cutting-Die assembled on the cutting machine.

28.What kind of things can be specifically cut with a Cutting Rule?+

Featured with diffferent specs, Cutting Rule can cut various kinds of materials like papers, plastics, leathers and even elctronics.

29.What is the difference between "Shaved" & "Ground" rules?+

The main difference is based on the "bevel finish", which decides cutting performances. Shaved rule ensures the durability and longer lifetime; while Ground rule provide better clean cut result.

30.What is the advantages of using "Super Ground Rule"?+

Superior properties are madatory for professional die-cutting of delicate materials like laminated substrates, films, metallized boards.

31.What are the characteristics and commonly used steel grades for hand saw ?+

A hand saw is a handheld tool used for manually cutting materials such as wood, metal, plastic, and more. High-quality hand saws are typically crafted from durable materials, offering excellent durability and resistance to wear. They often utilize heat-treated steel strip products made from carbon tool steel, which has undergone a heat treatment process to enhance its properties.

32.What steel grades are used for circular saws ?+

Circular saws possess powerful cutting capabilities and are typically paired with different types of saw blades to meet the cutting requirements of various materials. Circular saws often have the ability for high-speed cutting, allowing for efficient processing of large amounts of work and increasing production efficiency. Commonly used steel types include SK85, SK95, 1085 steel, SKS51, and SKS5. These steel types are frequently used by high-carbon steel users and carbon tool steel suppliers.

33.What are the commonly used materials for band saw with excellent cutting ability ?+

Band saws possess excellent cutting capabilities and can be used for cutting various materials. The cutting process involves utilizing a continuous band-like blade tool, allowing for precise straight or curved cuts. Band saw steel coils are commonly made from carbon tool steel products and alloy steel products, further optimized through heat treatment processes. Commonly used steel types include SK85, SK95, 1085 steel, and the SKS series.

34.Special Processing for trowel Quality Enhancement ?+

A trowel is an indispensable tool in masonry and plastering work, known for its durability, versatility, and ease of use. The blade of a trowel is typically made from high-quality stainless steel or carbon steel materials to ensure durability and rust resistance. To enhance aesthetics, special processes like polishing and coloring can be applied, further optimizing the product. Commonly used steel types include S65CM, SK85, 1065 steel, and 1085 steel.

35.Why do we perform surface grinding ?+

In addition to enhancing the visual texture, polishing materials also improves precision and adhesion in the subsequent manufacturing process.

36.What is Hardened and Tempered Steel Strip with Polished White ?+

Vibratory polishing" is a surface treatment technique that smoothens and brightens the surface of materials, enhancing the value and appeal of the product.

37.Which material is suitable for spring clips and tube bundling products ?+

Spring Clips are commonly used metal components for connecting and securing parts. They require durability and safety. Using carbon steel along with a heat treatment process can further optimize the product. The most commonly used specifications include S50C, SUP6, SUP10, and 1065 steel.

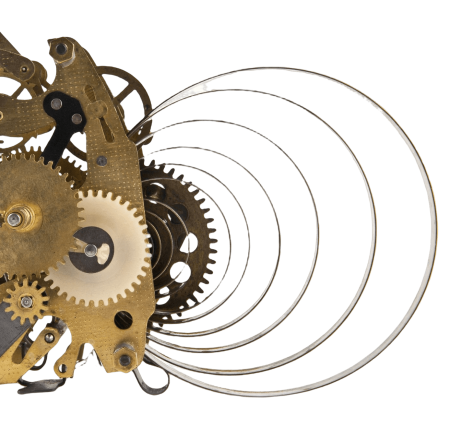

38.What are the characteristics and common types of spring steel ?+

Springs are elastic components capable of undergoing deformation and returning to their original shape; whereas carbon steel possesses excellent strength and hardness, allowing it to withstand high levels of stress and load while being easy to process. Therefore, it is the optimal choice for both spring suppliers and carbon steel suppliers. The most commonly used steel types include S50C, S65C, SK85, 1065 steel, 1085 steel, and the SUP series.

39.Where is Spring Steel used ?+

Spring steel is widely used in various industries, including the automotive industry, machinery manufacturing, electronic equipment, household appliances, and aerospace, among others. It is employed in the production of various types of springs to meet the diverse requirements for springs in different fields.

40.What is Spring Steel ?+

Spring steel is a type of steel specifically used for manufacturing springs. It possesses excellent elasticity and mechanical properties to accommodate the deformation and recovery characteristics required by springs in their applications

41.What material is suitable for automotive parts needing both toughness and strength ?+

Automotive parts typically require high strength and durability to withstand various road conditions and mechanical stresses. The selection and design of materials focus on providing sufficient strength and durability to ensure long-term reliability of the components. Ductile iron materials are well-suited for products that demand a combination of toughness and strength. Commonly used steel grades include S50C, S55C, S65C, SK85M, SUP6, SUP10, 1065 steel, and 1085 steel.

42.Which material is suitable for spring clips ?+

Spring washers are commonly used metal components for connecting and securing parts. They require durability and safety. Using carbon steel along with a heat treatment process can further optimize the product. The most commonly used specifications include S50C, SUP6, SUP10, and 1065 steel.

43.What are the characteristics and common grades of spring ?+

Springs are elastic components capable of undergoing deformation and returning to their original shape; whereas carbon steel possesses excellent strength and hardness, allowing it to withstand high levels of stress and load while being easy to process. Therefore, it is the optimal choice for both spring suppliers and carbon steel suppliers. The most commonly used steel types include S50C, S65C, SK85, 1065 steel, 1085 steel, and the SUP series.

44.Why use Bainitic Steel ?+

Traditional materials often exhibit higher hardness and strength but are relatively brittle. This means that when subjected to impact or stress, these materials are prone to fracture or failure. To address this issue, ductile iron materials employ specific processes and techniques to enhance their toughness and impact strength while maintaining a certain level of hardness and strength.

45.What is Bainitic Steel ?+

Bainitic steel is a special material that undergoes specific processing to enhance its toughness and impact strength. It exhibits good ductility and energy-absorption capabilities when subjected to high stress and impact loads, reducing the risk of fracture and damage, thereby improving product reliability and safety.

46.Pneumatic tools require durable materials and processes. What are the commonly used steel?+

Pneumatic tools are tools powered by compressed air and are typically made from durable materials capable of withstanding prolonged and high-load usage. Commonly used steel grades include SK85 and 1085 steel.

47.What are the characteristics and commonly used steel grades for hand saws ?+

A handsaw is a handheld tool used for manually cutting materials such as wood, metal, plastic, and more. High-quality handsaws are typically made from durable materials and exhibit good durability and wear resistance. They often utilize heat-treated steel strip products produced from carbon tool steel, enhanced through the process of heat treatment.

48.What are the characteristics and commonly used steel grades for box cutter ?+

A box cutteter is a commonly used tool employed for cutting, carving, and trimming various materials. High-quality utility knives are typically crafted from premium materials, exhibiting durability and corrosion resistance, allowing for extended usage without easy damage. The most frequently used steel grades for this purpose are SK85, SK95, and 1085.

49.What is alloy steel ?+